Brand Story

やさしさを編む、しあわせを着る。

手仕事のぬくもり、世界中のひとへ。UTOのカシミヤニット

UTOのカシミヤニットを頭からくぐると、

肌とこころに上質なやさしさが伝わってくる。

自分が気に入る自分になる。

静かに、自信のようなものが湧いてくる。

誰かと会いたくなる。

一枚のカシミヤニットができること。

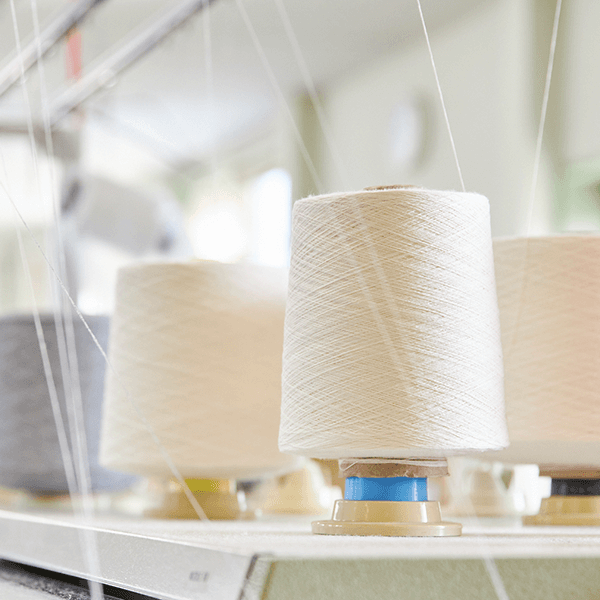

選び抜いたトップグレードの糸、磨き抜かれた職人の腕、

お客さまひとりひとりの身体にしっくりくる仕立て。

ひと編み、ひと編み、丁寧なものづくりの先には、

着る人の気持ちの温度をふっと上げることができると信じている

一度に大量の服をつくり、大量に消費するのではなく。

一生着続けたい、と想えるニットをこしらえたい。

笑顔がこぼれるほど心地いいニットで、

喧嘩をすることはムズカシイ。

ひとも地球も、しあわせであるために。

私たちは今日もカシミヤニットを手作りしています。

ご馳走のような、カシミヤニット

UTOは1992年に東京・青山で創業した

「日本製 カシミヤニット」ブランド。

岩手県北上市のカシミヤ職人が

オーダーメイドで1枚1枚

「手の温もり」を込めて作る

「あなたのためのカシミヤニット」です。